Key Benefits of Using an Industrial Coffee Grinder for Your Business

Key Benefits of Using an Industrial Coffee Grinder for Your Business

Blog Article

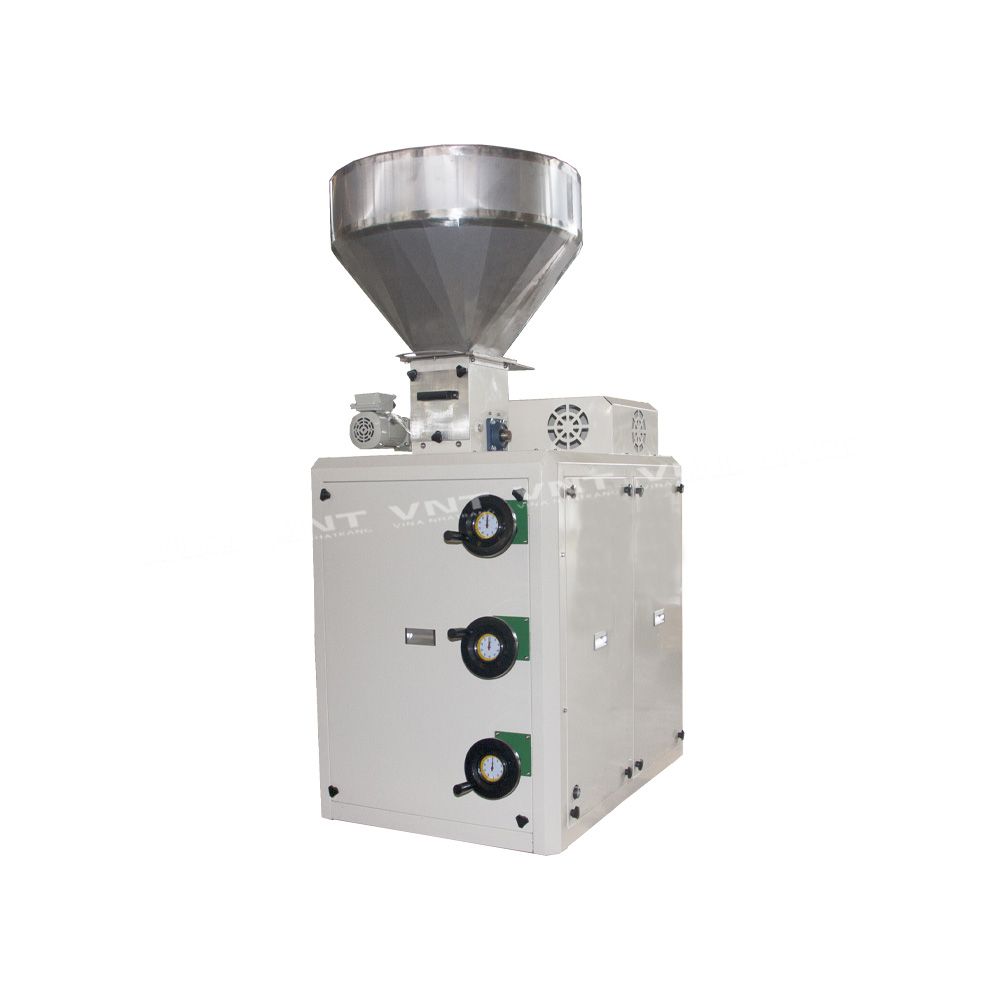

Industrial Coffee Grinder Guide: Increase Effectiveness and High Quality

In the competitive landscape of coffee manufacturing, selecting the ideal industrial coffee grinder plays a pivotal duty in enhancing both effectiveness and product high quality. Comprehending the nuances of various mill kinds and key attributes-- such as adjustable grind settings and durable building-- can substantially affect the final taste account of the coffee. The optimization of the grinding process, combined with diligent maintenance, is vital for maintaining performance over time. As we check out these important aspects, it comes to be evident that the ramifications extend past simple tools selection, influencing total business success in manner ins which necessitate closer examination.

Understanding Mill Kinds

When picking an industrial coffee grinder, comprehending the numerous kinds available is important for enhancing both flavor extraction and operational effectiveness. The 2 main kinds of mills are blade grinders and burr grinders.

Ultimately, choosing the ideal kind of mill is essential to preserving quality and efficiency in coffee production, making it critical for businesses to spend in high-grade burr mills for optimum results.

Key Functions to Take Into Consideration

Picking an industrial coffee grinder needs mindful consideration of a number of crucial functions that can considerably influence both performance and the overall coffee experience. One of the key elements to examine is the grinding system. Burr grinders are typically favored over blade mills, as they provide a consistent grind dimension, which is essential for ideal extraction and taste.

Another crucial feature is the grinder's capacity. Depending on the volume of coffee you need to procedure, select a design that can handle your needs without compromising rate or top quality. Additionally, consider the grind settings supplied. A functional grinder with several settings permits you to customize the grind size to different developing approaches, enhancing the coffee's flavor account.

Assess the grinder's sound level, specifically in a hectic coffee shop or manufacturing setting, where excessive noise can be turbulent. Spending in a grinder that stabilizes these attributes can considerably enhance both operational effectiveness and the high quality of the coffee offered.

Optimizing Grinding Refine

To accomplish the finest outcomes in coffee preparation, optimizing the grinding procedure is necessary. The grind size considerably affects removal, flavor, and total he has a good point quality of the made coffee.

Furthermore, checking the grinding speed can optimize the procedure. Slower grinding commonly produces much less heat, protecting delicate flavors and scents. On the other hand, faster grinding might create too much warm, adversely impacting the coffee's top quality.

Upkeep and Care Tips

Appropriate upkeep and care of industrial coffee grinders are necessary for making sure ideal efficiency and longevity. Normal cleansing is the structure of upkeep; deposit buildup can influence flavor and grinding efficiency. It is advisable to cleanse the grinder after each use, wiping down the exterior and getting rid of any kind of coffee grounds from the burrs.

In addition, inspect the grinding burrs for wear and tear. Plain burrs can jeopardize work uniformity, so they must be changed as required. Industrial Coffee Grinder. Regularly adjusting the grinder is also critical, as this keeps the desired work dimension for different developing approaches

Lubrication of moving parts should be done according to the supplier's specs, as this decreases friction and lengthens the life of the devices. It is necessary to use food-grade lubricating substances to ensure security and conformity with health laws.

Finally, maintain the grinder in a stable and dry environment to prevent rust and rust. By adhering to these maintenance and care tips, operators can enhance the effectiveness of their commercial coffee grinders while making sure top quality result and prolonged functional life.

Return on Investment Analysis

Assessing the roi (ROI) for commercial coffee mills is critical for organizations looking for to optimize their coffee manufacturing abilities. A comprehensive ROI analysis aids establish the financial viability of buying high-grade grinders, enabling organizations to consider the first prices against potential gains.

Examine the purchase cost of the grinder, including setup and any required modifications to existing facilities. High-performance mills frequently lead to minimized grinding time and enhanced throughput, which can significantly enhance efficiency.

Additionally, take into consideration the effect on product top quality. Industrial Coffee Grinder. Superior grinders generate an even more constant grind dimension, which can enhance flavor accounts and client contentment, inevitably driving sales. By enhancing the top quality click of the final item, organizations can validate greater pricing, leading to boosted profits

Conclusion

In summary, an industrial coffee mill plays a pivotal role in enhancing both effectiveness and product high quality within coffee manufacturing. Eventually, the strategic financial investment in a dependable grinder adds considerably to enhanced revenue and competition in the coffee sector.

In the competitive landscape of coffee manufacturing, choosing the appropriate industrial coffee grinder plays a pivotal duty in improving both performance and product top quality. The two main kinds of mills More Info are blade mills and burr grinders. Within the burr mill classification, there are level burr mills and conelike burr mills, each with its advantages. Burr grinders are normally chosen over blade grinders, as they give a constant grind dimension, which is crucial for ideal extraction and flavor.

In recap, an industrial coffee mill plays an essential role in boosting both performance and item top quality within coffee manufacturing.

Report this page